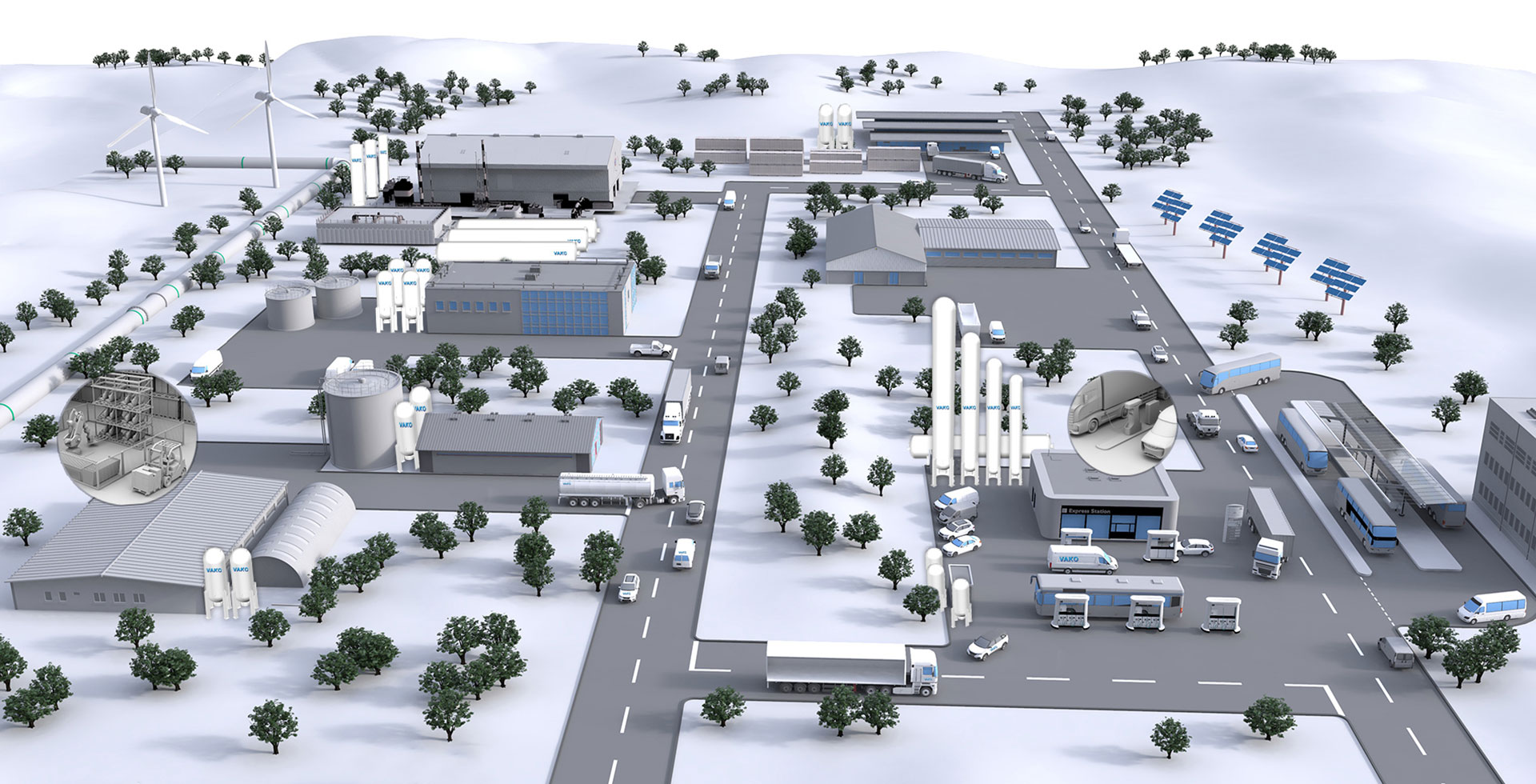

H₂ storage solutions from VAKO – with maximum safety and low life cycle costs

Storage systems offering maximum efficiency thanks to German manufacturing and engineering.

Hydrogen is the energy source of the future! However, it needs reliable and durable storage solutions to be economically viable. For more than 40 years, VAKO has been developing and manufacturing high-quality hydrogen storage systems that are used worldwide in industry, filling stations, energy projects, and research..

Tailor-made storage solutions for a wide range of applications

With diameters of up to 4,500 mm, lengths of up to 45,000 mm and operating pressures of up to 330 bar, we offer customized storage vessels for a wide range of applications: from electrolysis systems and filling stations to advanced industrial and specialty projects.

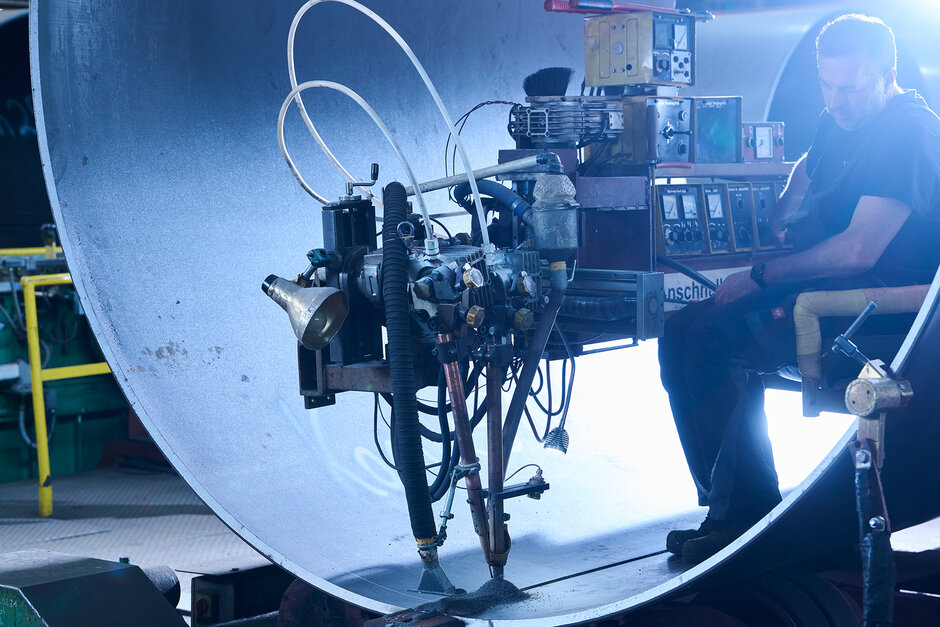

Precision down to the last detail

Quality begins with minutiae. We first create a clean basis for all further processing by selectively milling out the root layers. Imperfections are avoided and even the smallest deviations are corrected. The result: pressure vessels built from the inside-out to deliver precision, reliability, and a long service life.

for logistics centers

for electrolysers

for the food industry

and uninterrupted power supply

for refueling, e.g. forklifting trucks

for metal processing

for industrial applications,

for filling stations, e.g. cars, buses, trucks

for emergency power supply

MORE SAFETY. MORE EFFICIENCY.

MORE FUTURE.

More than 40 years of experience

- Expertise in pressure vessel construction since 1968.

- Expertise in hydrogen storage since 1980.

Maximum safety

- Certified type 1 pressure vessels acc. to the highest international standards.

More efficiency

- Up to 80% lower inspection costs with the VAKO testing concept.

Individual solutions

- Customized storage – for industry, research, infrastructure, mobility, and specialty projects.