Safe hydrogen storage vessels and purification vessels as well as high-pressure vessels from VAKO.

Competence from the manufacturer.

For more than 40 years, VAKO GmbH & Co. KG has stood for uncompromising safety and exceptional quality in type-1 hydrogen storage vessels. As a family-owned company in Kreuztal, Germany, we combine tradition with innovation and supply sustainable storage solutions that are used worldwide in industry, research, infrastructure, mobility, special projects, and the energy transition.

VAKO’s unique testing concept significantly reduces recurring maintenance costs and enables all inspections to be conducted from outside the pressure vessel without any hydrogen losses, flushing, or downtime – for maximum cost effectiveness and minimal operational impact. We easily exceed established market standards with around 60 specialists, cutting-edge manufacturing technology, and 100% weld seam testing using complementary processes.

VAKO drives the push for a safe, climate-friendly energy future with its certified, sustainable storage solutions in standard sizes or custom designs up to 330 bar.

Holistic hydrogen storage solutions.

Hydrogen storage vessels

From design to commissioning – VAKO offers an end-to-end service for type 1 hydrogen storage vessels. We are a one-stop shop for engineering, manufacturing, installation, and after-sales service. We specialize in cost-effective, future-proof storage solutions.

Reducing complexity – shaping the future.

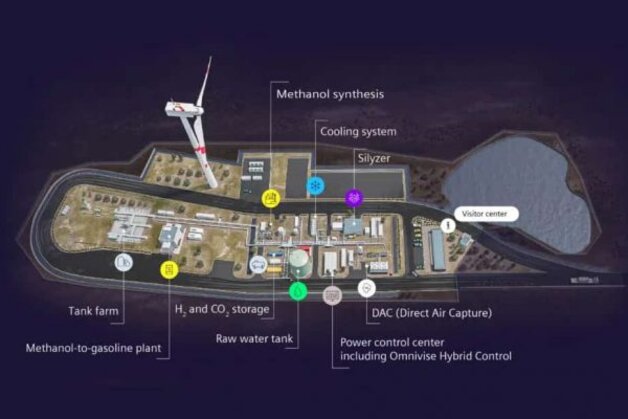

Green energy

The energy transition needs partners who combine technology and experience. VAKO supports green energy projects with storage solutions. We advise, develop, and deliver – from the idea to commissioning.

Custom-made pressure vessels – standardized and customized solutions.

Pressure vessel manufacturing

We manufacture certified, sustainable storage solutions – from standard sizes all the way to custom designs up to 330 bar. Our pressure vessels are durable and highly customizable. VAKO’s unique testing concept ensures efficiency and sustainably reduces operating costs

Surface treatment and corrosion protection for a long service life.

Surface treatment technology

VAKO protects hydrogen storage vessels and high-pressure vessels with cutting-edge processes, from blasting to special coatings. That keeps equipment reliable, efficient, and high-quality over long periods, even under rough conditions.